Comifo

Comifo  Helen Lin

Helen Lin  Flower Li

X

Flower Li

X

Contact Us

Comifo Duct Manufacture Machine Co., Ltd.

Tel:+86-20-89817565

Fax: +86-20-89814865

E_mail: comifo@21cn.net

Skype: comifo-helen

Wechat:comifo-helen

Whatsapp:+86-18988833035

Web: http://www.comifomachine.com/

NewWeb: http://www.gzcomifo.com/

Address: Room 403, East Tower, Jiadu Business Building, No.64-66,Jianzhong Road, Tianhe Software Park, Guangzhou, P.R.China.

Links

Comifo's new product gained busiess attention on Air-condition Equipment Show 2005 in China.

7th-9th April 2011 in Shanghai China, Booth No.: E6H01.

Duct Compact Line II

Products Information:

Products Information:

Comifo provides compact lines for small and medium sized duct factories and duct installation contractors. Compact line can be either a stand alone system or the start of a complete automatic fabricating system. It is the starter of duct manufacture, also it can be taken right to the construction site. Its control system adopts specific software and realizes one person operation, which saves labor cost.

Developed from Compact Line I, Compact Line II is with hydraulic punching square and notching.

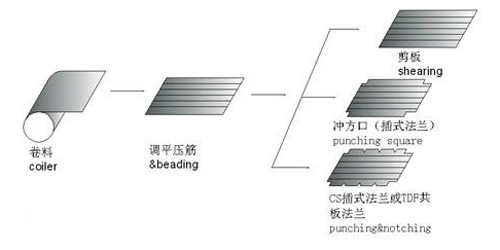

The work flow: coil-straightening-beading-punching-notching-shearing

Standard Features:

1.Twin-motor driven dual-decoiling, selectable coils stand by, maximum capacity of 5-ton per station (optional: up to 10-ton per station)

2.Straightening/flattening -Air pressure controlled six(6) rolls straightenerNo adjustment required when changing from 18 to 27 gauge (0.4-1.2mm) material

3.Air pressure controlled ring type beading rolls with five beading rings-optional by remove beading rings or uplift the beading rolls

4.Accurate PLC control unit, Preset cutting size , touchscreen-easy operate

5.0-18m/min feeding speed,fast acting back gauge,7 seconds per cutting for a 1m length sheet metal

Capabilities:

1.Alternative width for 4(1300mm) or 5(1550) material

2.Thickness: 18-27ga (0.4-1.2mm)

3.Shearing tolerance of ±0.5mm

4.Hydraulic folding diagonal tolerance of ±0.5mm

5.0-54FPM (0-18m/min) feeding speed,fast acting back gauge

COMPACT LINE II

Comifos Compact Line II consists of cradle style decoiler, 6-roller straightener, ring-type beader and hydraulic shearer,punching and notching. It processes 4(1300mm) or 5(1550mm) galvanized steel for 18 to 27 gauge (0.4-1.2mm) material into blank for plasma cutting machine.

|

Model No. |

Max Coil Width |

Thickness Range |

Speed |

Shearing Tolerance |

Diagonal Tolerance |

|

CAL2-1.2x1300 |

1300mm |

0.4-1.2mm |

0-18m/min |

±0.5mm |

±0.5mm |

|

CAL2-1.2x1600 |

1600mm |

0.4-1.2mm |

0-18m/min |

±0.5mm |

±0.5mm |

Note:

1.Cut to length or cut blank for plasma cutting machine

2.1 Punching and notching for “C” “S” cleat duct. It can cut different types of notches such as ”L”, “U” and “口”. It can also cut blank for “C” and “S” cleat flange machine.

2.2 Cutting blank for TDF flange machine. It can be used with TDF flange machine and folding machine.

2.3 Cutting blank for angle iron flange or “Z” shape flange machine.

3. Cutting blank for TTF/LT mate flange.

Stations: coil-straightening-beading- punching square -notching-shearing

Work Flow:

Previous:Duct Compact Line III Next:Duct Compact Line I